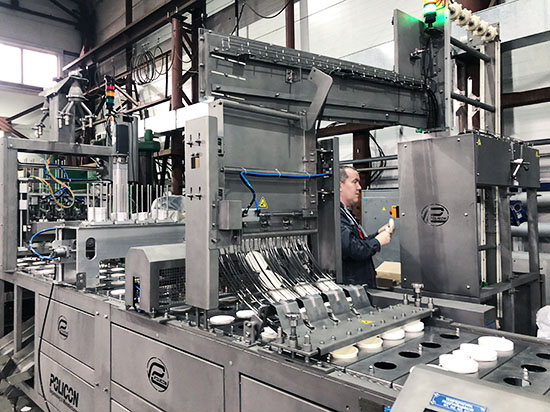

Acceptance tests of the RIO 4x4 multi line have been completed

15.04.2024

When April 1 is celebrated in many countries as April Fool's Day, we had no time for jokes. Monday turned out to be very serious and responsible - on this day, representatives of the customer from a famous ice cream factory in the Volga region arrived for the final tests. On the agenda is the delivery of the automated RIO 4x4 multi line (4-line for 4 types of product).

1.5 years have passed since the customers first met the company JSCo Policon. As a result of fruitful cooperation and interest of both parties, constructive dialogue and taking into account all technical wishes, sparkling design, careful assembly, we can definitely say everything is real if we really want to!

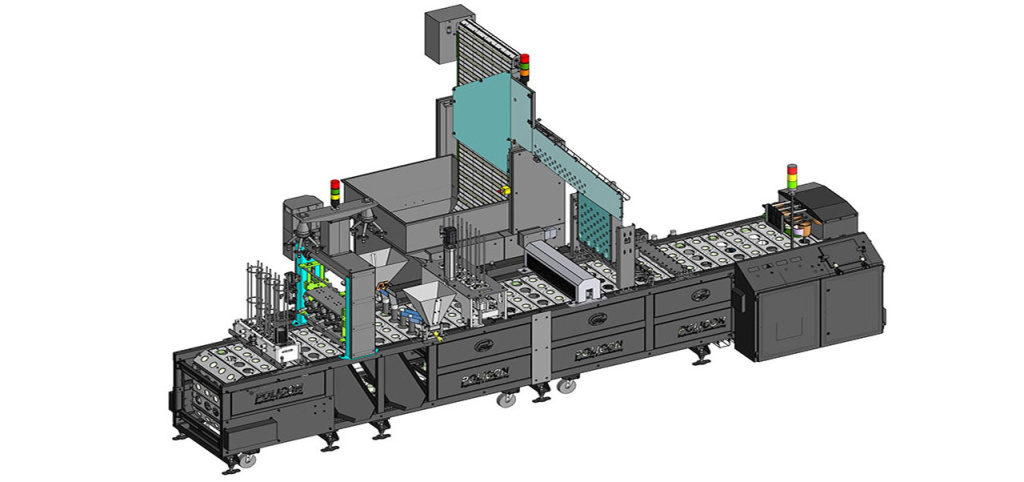

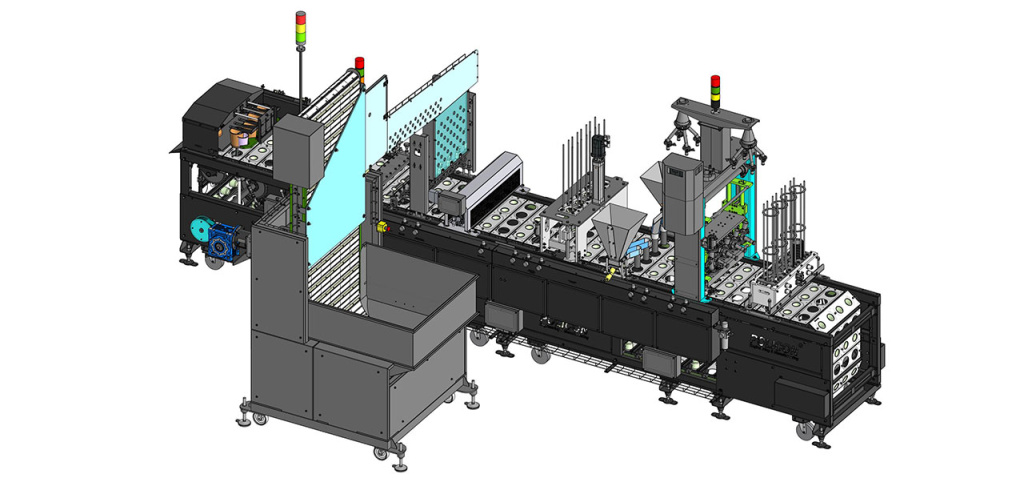

RIO 4x4 multiline is a four-line conveyor with a servo drive and additional equipment installed on it for the production of ice cream in four types of containers: paper cup 65 g, plastic cup Polex 374, paper bucket SPAR1, bucket 500 g, with capping options certain glasses and the introduction of various fillers.

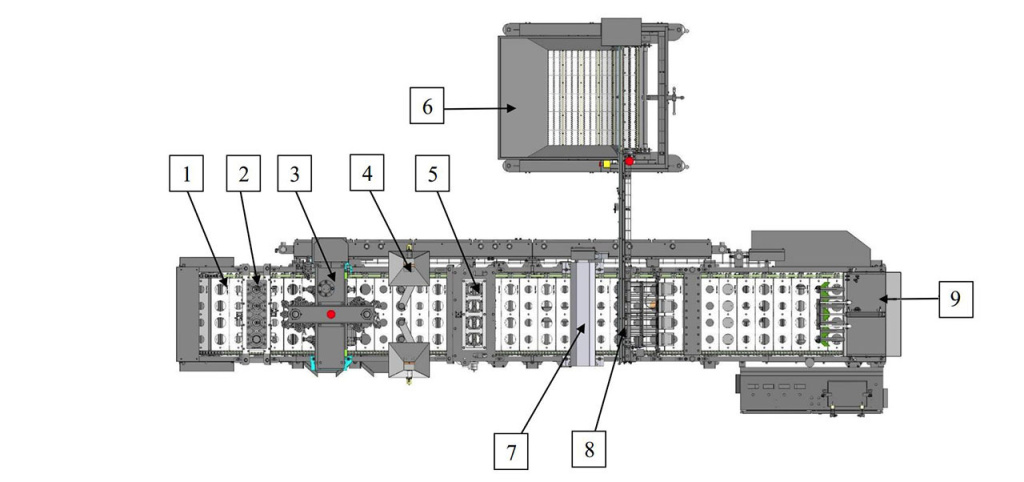

The line consists of various units installed on the frame and a separate automatic paper cover feeding device (several types):

1. Main drive frame with a set of plates.

2. Cups loading station.

3. Unit for raising and lowering two-flow and four-flow two-color ice cream dispensers.

4. Station for sprinkling the product with dry ingredients.

5. Cups lid loading station (three complects).

6. Automatic paper lid feeding station.

7. Devices for sealing the plate of a 65 g cup. and SPAR 1 bucket.

8. Capping station with a paper lid.

9. Finished product extraction station.

Also installed on the frame is a control cabinet with an HMI operator panel.

Productivity of the RIO 4x4 multi line:

- at least 6,300 pieces/hour for a 65 g paper cup;

- at least 6,300 pieces/hour for a Polex 374 plastic cup;

- at least 6,300 pieces/hour for a paper bucket SPAR1;

- at least 3,000 pieces/hour for a 500 g bucket.

Two days of hard work by the entire team and the delivery of equipment culminated in a natural victory. The customer's representatives were satisfied with the result and made minor adjustments for better operation of the line. All improvements to the RIO 4x4 multi line have already been carried out; at the beginning of next week, the equipment will leave for the ice cream factory to produce a wide range of flavors and forms of ice cream. But we don’t stop - there are still many interesting tasks, automation projects ahead... anything is possible!

Contacts

Tel./Fax: +7 (3812) 36 74 02, 36 74 12, 36 78 54, 48 48 30

e-mail: info@policon-rt.ru

66 Leningradskiy prospekt, Moscow, 125315, Russia

Tel: +7 (499) 649 60 10, +7 (915) 198 09 21

e-mail: dech@policon-rt.ru

Contacts

Tel./Fax: +7 (3812) 36 74 02, 36 74 12, 36 78 54, 48 48 30

e-mail: info@policon-rt.ru

66 Leningradskiy prospekt, Moscow, 125315, Russia

Tel: +7 (499) 649 60 10, +7 (915) 198 09 21

e-mail: dech@policon-rt.ru